Students get SWEPCO Turk insights

By Submitted, 12/3/18 12:14 PM

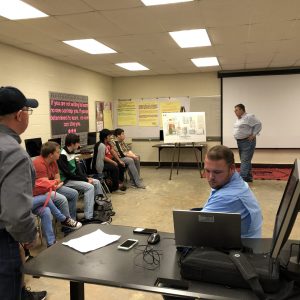

David Roberts, operations superintendent for the AEP-Southwestern Electric Power Co. John W. Turk Jr. Power Plant at Fulton takes Hope High School Noble Impact students through the processes involved in operating the $2 billion electrical power plant. Roberts, along with operations specialist Gary Palmer and plant system operator Dustin H. Freeman, also explained the employment opportunities available at the Hempstead County-based facility.

HOPE – Students in the Noble Impact program at Hope High School learned recently how the newest coal-fired power plant in the nation remains safe, environmentally friendly, and efficient while producing electrical power for customers across three states and employing 112 people locally.

Southwestern Electric Power Company (SWEPCO), an AEP company, the Hope Public Schools “Manufacturer of the Month” for November, was represented by four employees who took Terri Hoglund’s classes on a virtual tour of the processes and jobs involved in producing electricity at John W. Turk Jr. Power Plant at Fulton.

As Turk Operations Superintendent David Roberts, a 33-year SWEPCO employee, Operations Specialist Garry Palmer, a 30-year SWEPCO employee, and Plant System Operator Dustin H. Freeman, a seven-year SWEPCO employee, explained the processes involved in generating electricity at the Turk plant, they also discussed how they came to work at a $2-billion power plant.

Roberts, who has a degree in education, began his career in electrical power production at West Texas Utilities in Abilene, Texas, in 1984. He began at the Fort Phantom Power Station in Abilene.

“I started as a Trainee One,” he said. “I had a teaching degree and could have been an agri teacher if I’d wanted.”

Instead, he progressed from Abilene to SWEPCO’s Flint Creek Power Station near Gentry, Ark., in 2004, and transferred into the start-up of the Turk plant in 2010.

“I started as a custodian,” Palmer said. “But, I liked learning.”

He said he took on every new job that he could learn before he transferred to the Turk plant in 2010 after working at the WTU Oklaunion Power Station since 1988.

“You have to start somewhere, and it’s not working at the top,” Palmer quipped.

Freeman took advantage of the University of Arkansas Hope “Power Plant Technology” program which was developed in conjunction with the construction of the Turk plant.

He began at Turk as an instrument technician as a result, and has since completed a degree in engineering at Texas A&M University at Texarkana in order to move into the job as a plant system operator.

“SWEPCO brought in about half of the folks that operate the plant,” Roberts said. “The rest of the 112 employees came from right here in Hope at the University of Arkansas Community College at Hope.”

After Roberts and Palmer walked the students through the electricity production process at Turk, SWEPCO Senior Communications Consultant Karen Wissing addressed the opportunities that can be available for HHS students after graduation with a college degree or without a degree.

She pointed out that the variety of applications for science, math, geography, art, law, business, safety and other fields of study at AEP/SWEPCO is extensive.

“SWEPCO has 535,000 customers in Texas, Arkansas and Louisiana; it’s a huge undertaking,” she said.

The company currently employees 1,700 personnel across those three states, and offers highly competitive pay scales, holiday benefits, personal leave time, vacation time, health insurance and retirement plans.

“They understand that you are a person; you have a family,” Wissing said.

She said high school graduates who want to grow with the company can do so.

“All regular full-time employees are eligible to receive financial assistance through AEP’s Educational Assistance program,” Wissing said. “This includes 75 percent of registration fees, tuition, and lab fees, along with 100 percent reimbursement for books.”

She said she is currently studying for a master’s degree in business administration through the company program.

The Turk plant operates 24-hours a day, 365-days annually to produce electrical energy from Powder River Basin, Wyoming, coal, Roberts said.

“Power production is about converting one form of energy into another,” he said.

That is accomplished at the Turk plant by turning chemical energy from coal into thermal energy as steam, to create mechanical energy from a turbine that produces electrical energy from a generator on a massive scale, Roberts said.

The Turk plant has a capacity of 600 megawatts of electrical power production.